Version 5 is different kind of beast, since it’s made with a woven fabric and fully lined … but aside from a lot of tedious hand-sewing, it’s really not that difficult.

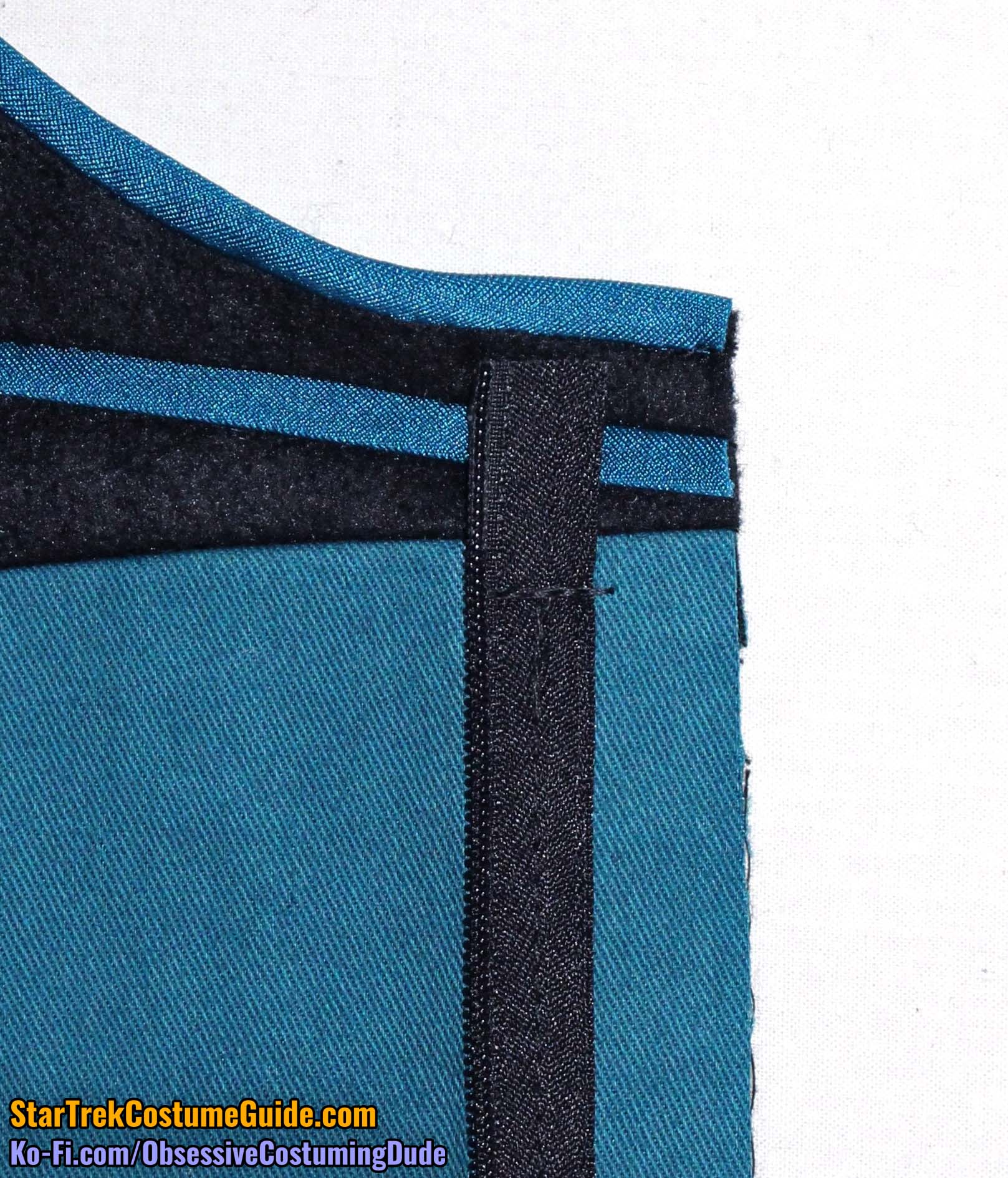

The yoke construction is the same as with the previous versions, even though the yoke was made with a woven fabric instead of jumbo spandex.

STEP 1 - Front Assembly

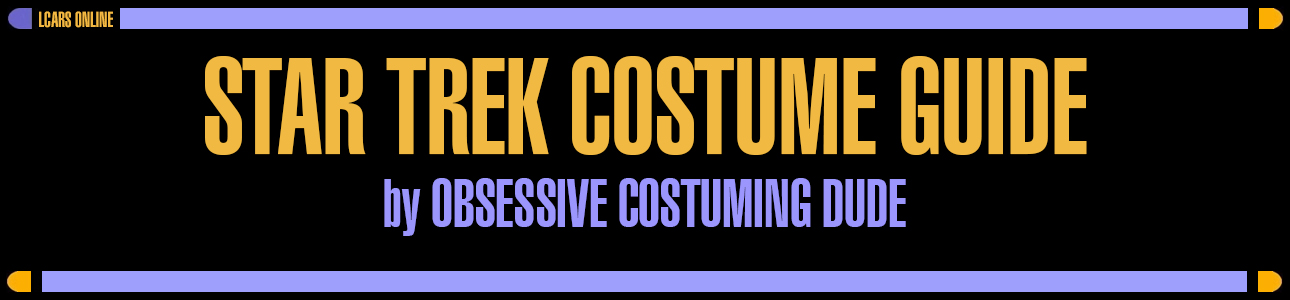

For the front yoke assembly, you’ll need the upper front yoke (piece A), lower front yoke (piece B), and front yoke piping (piece F).

Begin by pressing your front yoke piping in half, lengthwise.

(And if you’re “cheating” and using the same jumbo spandex as the body panels, remember to fold the matte/”dull” sides together so the trim is shiny-sides-out.)

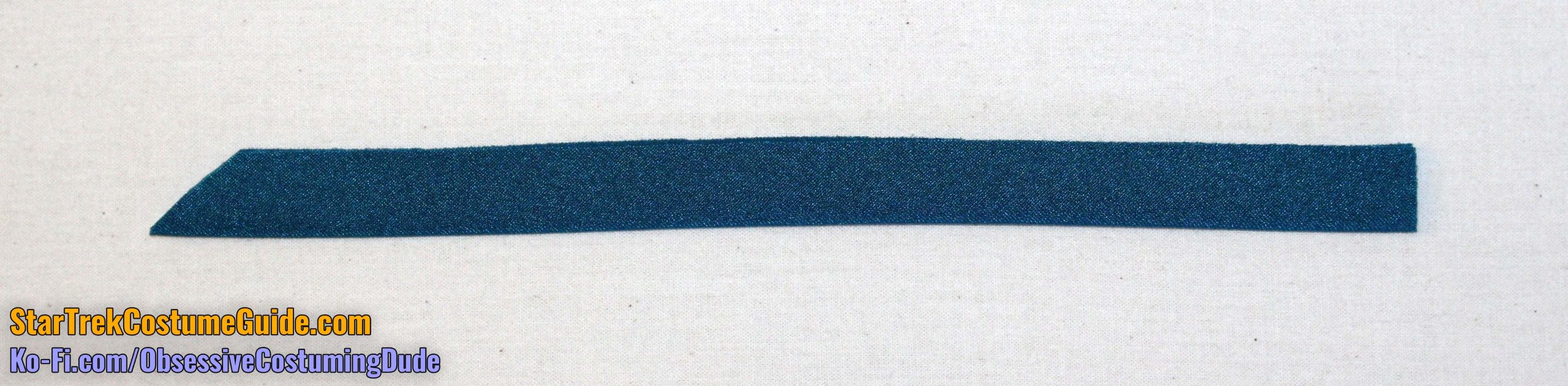

Pin the front yoke piping to the lower front yoke, folded side down, with the upper and centermost edges flush.

Using black thread, sew the front yoke piping to the lower front yoke ⅜” from the upper edge.

Sew the upper yoke to the lower yoke with ⅜” seam allowance, exactly over the previous stitch line.

Press the upper yoke and seam allowances upward.

TIP: Use a quilting/walking foot to sew through all those layers, to help prevent undesired stretching and/or sliding.

Pull the yoke seam allowances out of the way, and carefully trim the piping seam allowances down to ⅛”.

Press the seam allowances upward again.

OPTIONAL: Interface your center front body panels (piece 3A) with a lightweight hair canvas or lightweight fusible interfacing. I don’t know whether or not the original v5 medical smock(s) were interfaced like this, but the season 2 admiral uniform I examined was. With that uniform jacket also being made of superfine wool gabardine, by the same costume designer the same production year, I think it’s safe to assume that the version 5 smocks may have been interfaced, too.

OPTIONAL: Interface your center front body panels (piece 3A) with a lightweight hair canvas or lightweight fusible interfacing. I don’t know whether or not the original v5 medical smock(s) were interfaced like this, but the season 2 admiral uniform I examined was. With that uniform jacket also being made of superfine wool gabardine, by the same costume designer the same production year, I think it’s safe to assume that the version 5 smocks may have been interfaced, too.

OPTIONAL: I suggest interfacing the sleeve hem areas in the same manner.

Sew the front sleeve (piece 3E) to the front at the armscye.

I don’t know if this was done on the original smocks, but on tailored jackets, the lower armscye seam is typically reinforced with a second row of stitching, ⅛” inside the first, and the seam allowances trimmed are down to ¼”.

In the absence of any evidence to the contrary, I suggest doing so here.

Press the sleeve (and seam allowances) away from the front.

Using black thread, sew the front yoke assembly to the upper front body of the smock.

Press the seam allowances open.

Repeat for the other front assembly.

STEP 2 - Back Assembly

NOTE: On the screen-used Dr. Pulaski (v1) smock I examined, there was some extra material in the lower/outer area of the back yoke. I included it in my (Tailors Gone Wild) sewing pattern since it was there on the original, but in my experience it can cause some unwanted bulging in that area on a finished uniform, so I suggest trimming it away for a better fit. Simply make a graceful downward curve from the center back to each lower/outer corner of the lower back yoke (piece D).

Construct the back yoke assembly as described previously for the front yoke.

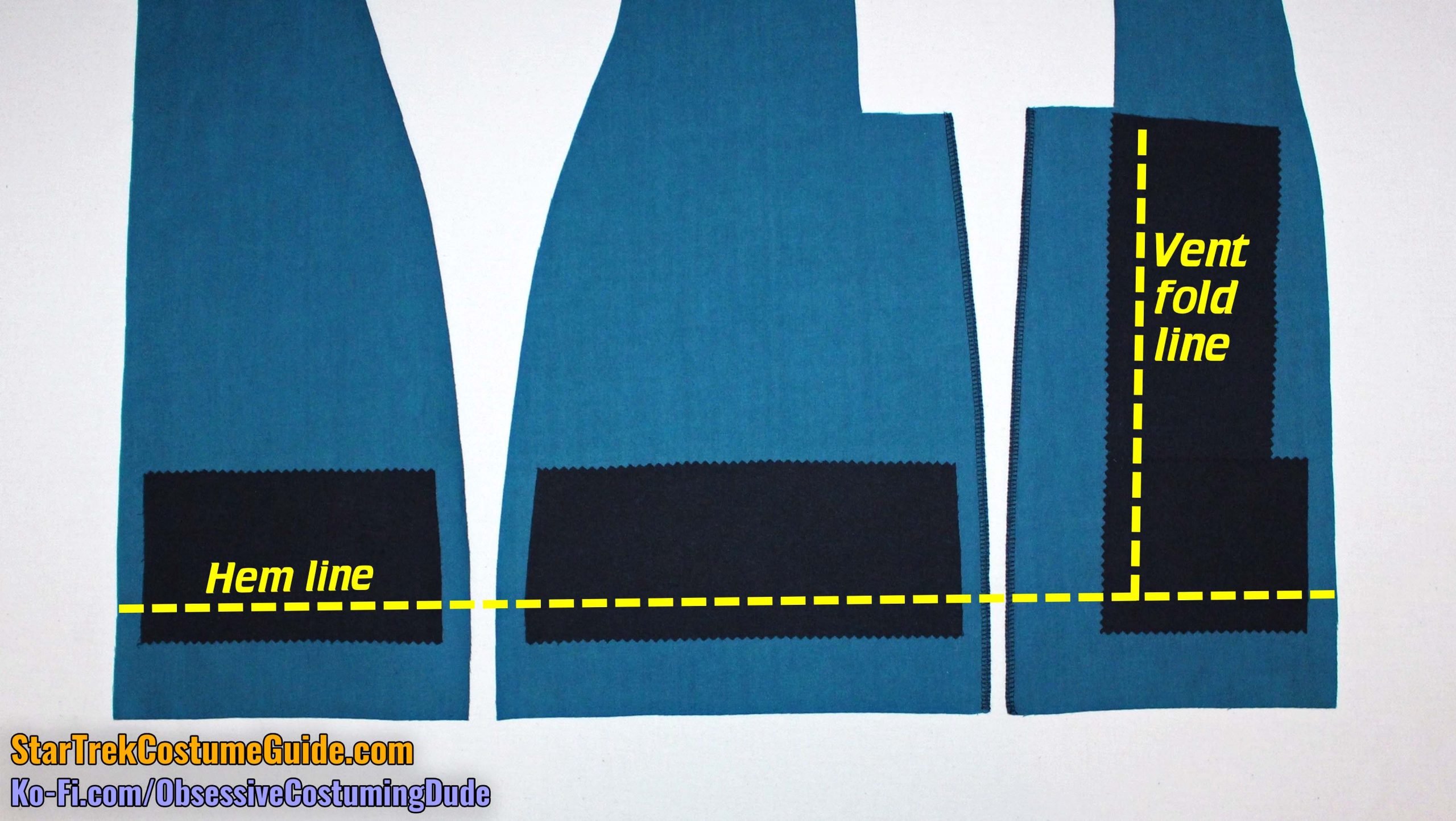

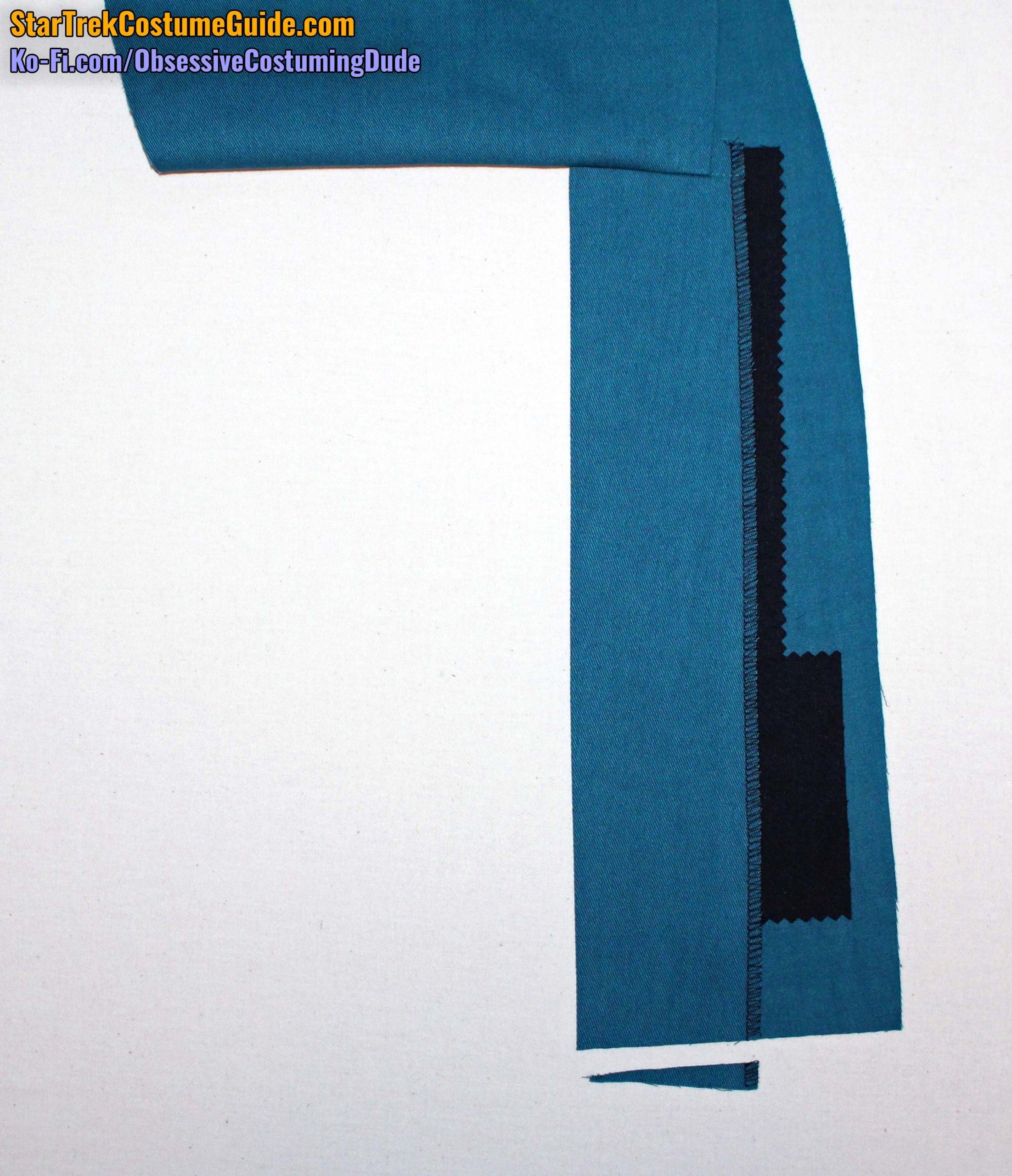

Serge the edge of the vent on the center back (piece 3D).

Sew the side back (piece 3C) to the center back (piece 3D), along the side and upper vent edges.

(Note that the center back will extend ½” past the folded edge of the side back.)

Shorten your stitch length and stitch around the corner of the vent again to reinforce the seam.

Sew the back sleeve (piece 3F) to the back.

Press the sleeve (and seam allowances) away from center.

Repeat for the other back assembly.

Sew the two back assemblies together along the center back.

Press the seam allowances open.

Using black thread, sew the back yoke to the back assembly.

Press the seam allowances open.

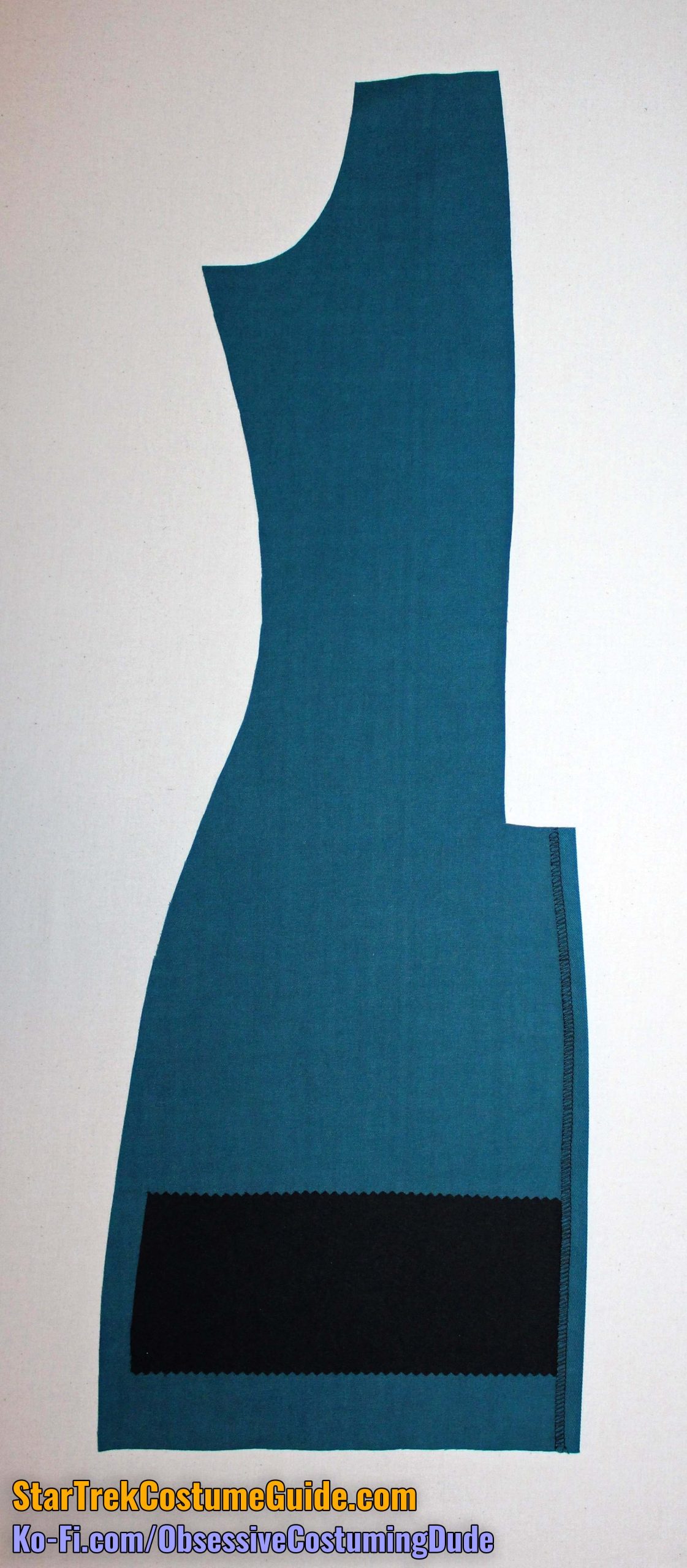

Your back assembly should now look like this:

STEP 3 - Fronts to Back

Sew the front and back assemblies together along the yoke/outer sleeve seams, matching yoke piping and seam lines.

TIP: Pin the assemblies together, then baste across the yoke piping and yoke/sleeve seam lines before sewing! Turn the garment right side out, check to make the sure the seams are properly aligned, adjust your basting if necessary, and once satisfied of proper alignment, THEN sew the assemblies together!

TIP: Use a quilting/walking foot to sew across the yoke piping, or even the entire shoulder/outer sleeve seam.

TIP: I like to use black thread for the yoke, and teal thread for the sleeves, simply because I prefer to sew with a matching thread color. If you don’t want to switch for this seam, I suggest using only black.

Press the seam allowances open.

Using black thread, stay-stitch the neckline ¼” from the edge.

As you may recall, the unlike the neckline trim on other TNG-era uniforms, the neckline trim on the screen-used Dr. Pulaski (v1) smock I examined was attached as a binding along the edge (as opposed to a trim that extended from underneath).

Pin your neckline trim (piece E) to the yoke along the neckline, edges flush.

Sew your neckline trim to the yoke approximately 3/16” from the edge.

Wrap the neckline trim snugly around the edge and pin the underside of the trim into place.

(I suggest trimming away as much of the upper yoke/lower yoke/piping seam allowance as possible at the center front to reduce bulk and help the underside of the trim sit flatter.)

Again using black thread, “stitch-in-the-ditch” along the lower edge of the neckline trim.

Catch-stitch the seam allowances to the underside of the yoke, catching only a thread of the garment fabric so your stitches won’t show on the right side.

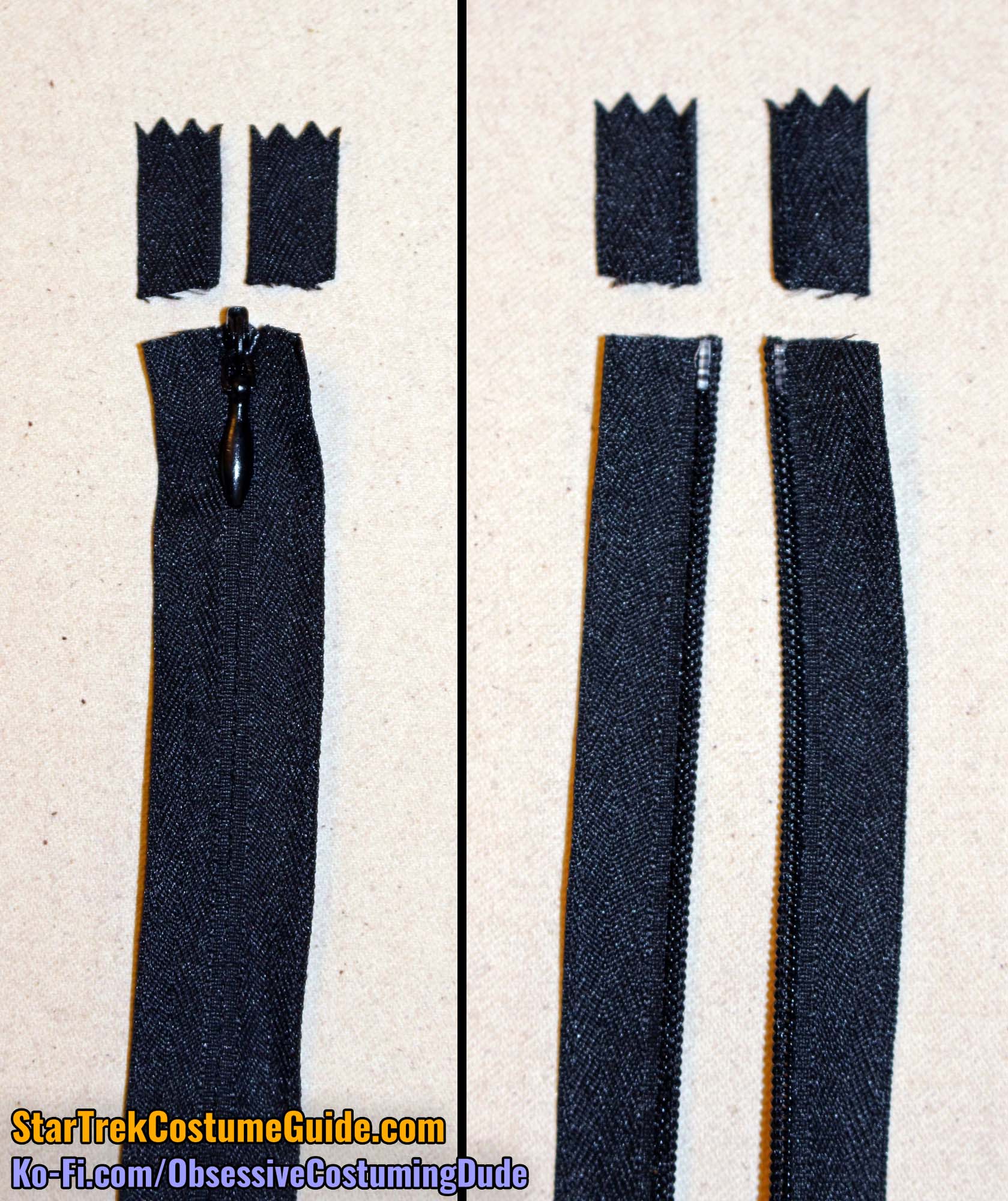

STEP 4 - Zipper

On the screen-used Dr. Pulaski (v1) smock I examined, the excess zipper tape at the top of the zipper was simply turned under and stitched down.

You’re obviously free to do that if you’d like, but I prefer to cut off the excess zipper tape directly above the zipper stop and apply some liquid fray preventer to the new upper edges.

Position your zipper on the front of the smock so it extends upward approximately ¾” above the yoke/body seam line. (The top of the zipper should be flush with the bottom of the neckline trim.)

Using your invisible zipper foot, baste the zipper to the smock with 1” seam allowance, leaving the uppermost 1” of the zipper left hanging free.

Close the zipper to make sure everything is properly aligned. (Keep a sharp eye on the waistband!)

If necessary, remove the basting stitching and adjust as-needed.

Once satisfied of the zipper’s positioning and waistband alignment across the center, sew the zipper to the smock, again leaving the uppermost 1” of the zipper left hanging free.

Then horizontally stitch across the zipper tape several times 1” from the top of the zipper (¼” from the bottom of the yoke) to reinforce it where it was left hanging free.

Stitch the zipper tape to the seam allowance again, approximately ¼” away from the zipper teeth.

Using teal thread, sew the lower center front closed beneath the zipper (again, with 1” seam allowance).

Press the seam allowances open.

Turn the upper front seam allowances under and tack them into place by hand, taking care that your stitches don’t show through on the right side of the garment.

Hand-sew three hook-and-eye closures to the seam allowances, again making sure your stitches don’t show on the right side.

STEP 5 - Finishing

Unfold the back vent and press the lower hem allowance upward.

Hand-sew the lower hem allowances into place, catching only the interfacing above the allowance so your hem stitching doesn’t show through to the right side of the garment.

Fold the back vent allowances back under and hand-sew them into place as well.

Repeat for the center back, and slip-stitch the bottom of the vent to the hem allowance.

Fold the back vent allowances back under and hand-sew them into place as well.

Press the sleeve hem allowance upward and hand-sew the hem allowances into place.

NOTE: On lined/tailored jackets, shoulder pads are usually permanently attached between the jacket “shell” and lining layers. If you want to sew and conceal yours in this manner, go ahead and do so now (before moving on to the lining assembly.) However, in this case I suggest lining the smock and then attaching the shoulder pads – perhaps with snaps – to allow for more convenient dry cleaning (should the need arise).

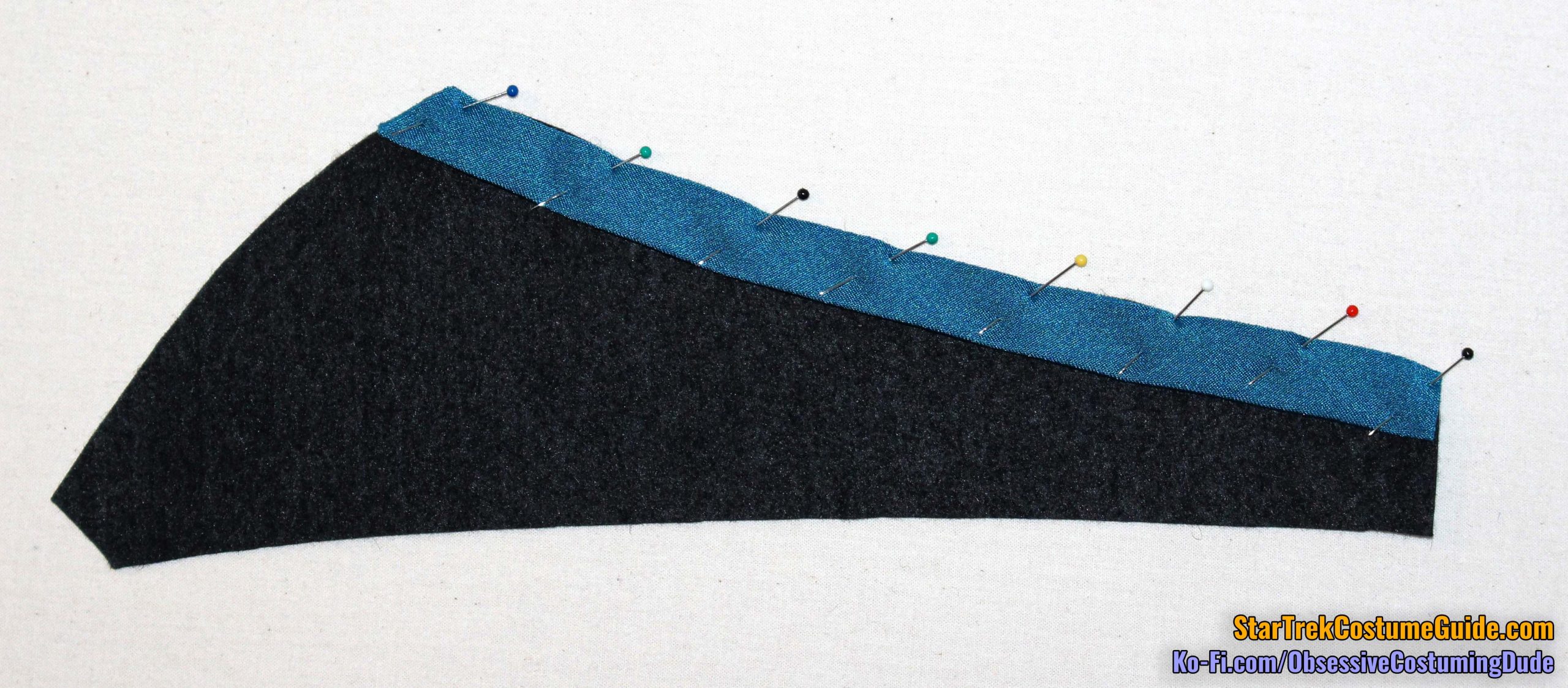

For the lining assembly, use all the corresponding yoke, body panel, and sleeve pieces; simply cut two each in black lining.

And for the most part, constructing the lining assembly is the same basic process as the smock “shell.”

Sew the upper front yoke and lower front yoke together with ⅜” seam allowance, omitting the yoke piping, and press the seam allowances upward.

Sew the center front and side front lining panels together and press the seam allowances toward the front. (I suggest tapering the ½” seam allowance down to ⅜” for the majority of the seam, to provide the lining assembly with some extra wearing ease.)

Sew the front sleeve to the front lining assembly. Stitch again ⅛” inside the previous stitch line, trim the seam allowances down to ¼”, and press the sleeve/seam allowances away from the front.

Sew the front yoke assembly to the front assembly and press the seam allowances open.

Repeat for the other front assembly.

Sew the upper back yoke and lower back yoke together with ⅜” seam allowance, omitting the yoke piping, and press the seam allowances upward.

Press the side back lining vent allowance under.

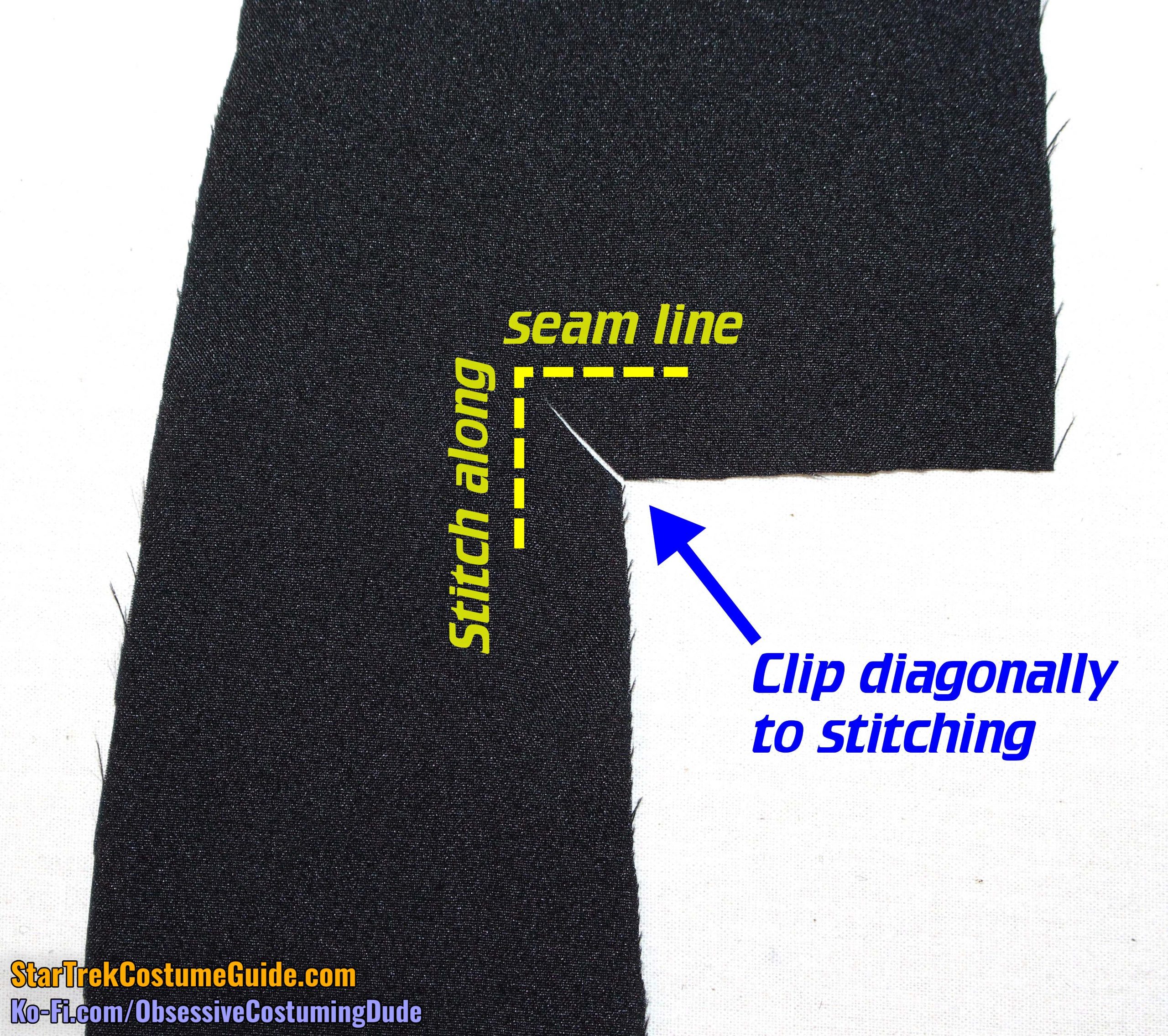

On the center back, reinforce the upper corner of the vent with a short row of stitching, and clip the seam allowance diagonally up to the corner of the stitching.

Press the seam allowances toward the center back.

With the lining assembly facing upward (wrong side downward), pull the upper layers out of the way until the upper vent allowances are visible.

Sew the upper vent allowances together along the seam line.

Sew the back sleeve lining to the back assembly, as described previously.

Repeat for the other back lining assembly.

Sew the back lining assemblies together along the center back, and press the seam allowances open.

Sew the back yoke lining assembly to the back lining assembly, and press the seam allowances open.

Sew the front and back lining assemblies together along the yoke/outer sleeve seams, and press the seam allowances open. (I suggest tapering the ½” seam allowance down to ⅜”, to provide the lining assembly with a bit some extra wearing ease.)

Sew the front and back lining assemblies together along the sides/inner sleeve seams, and press those seam allowances open as well. (Again, I suggest tapering the ½” seam allowance down to ⅜”.)

Trim ⅜” off of the bottom edges of your body lining assembly.

Trim ½” off of the bottom edges of your sleeve lining.

Unfold the side back lining’s vent allowance.

Press the lining body’s hem allowance upward.

Press the side back lining’s vent allowance back into place, over the hem allowance.

Press the center front lining’s seam allowance (1”) under.

I suggest unfolding the hem allowance and sewing the bottommost 5-6” of the center front lining panels together, then pressing the seam allowances open.

Press the lower front hem allowance upward again.

Press the neckline edge under approximately 3/16”.

Now come several hours of hand sewing … some people find it tedious and boring, others find it relaxing and cathartic, but it must be done!

Turn the smock inside out and “wrap” the lining assembly around it so the two are wrong-sides-together.

Pin the two layers together around the neckline. The folded edge of the lining should be flush with the stitching on the underside of the neckline trim.

Pin the two layers together along the center front. I like to position the lining about ¼” away from the actual zipper teeth.

Slip-stitch the lining assembly to the smock around the neckline and front edges.

I like to leave the upper front inch or so left free, as not to interfere with the “floating” zipper and hook-and-eye closures at the top.

The folded edges of the sleeve lining should be ½” above the sleeve hem line.

Hand-sew the lining to the sleeve’s hem allowance about 1” to 1 ¼” above the folded edge, forming a jump pleat for wearing ease.

Repeat for the other sleeve.

Turn the smock right-sides-out.

The lower folded edge of the lining assembly should be ⅜” above the hem line.

Hand-sew the lower lining to the lower hem allowance, again forming a jump pleat at the bottom for wearing ease.

Slip-stitch or fell-stitch the edges of the lining to the side back edges of the vent.

Repeat for the center back lining panels.

Although (as of the writing of this tutorial) I cannot conclusively say for sure, I believe the original TNG medical smocks were typically worn with the same style of custom-made shoulder pads as those on the screen-used TNG skant I examined (and other TNG-era uniforms).

You can use regular, store-bought raglan shoulder pads if you want, but I’m not aware of any as large as the originals and I don’t think the end result looks as good.

Should you wish to make a pair of replica shoulder pads (more akin to those on the screen-used TNG skants and TNG jumpsuits), here’s how. 🙂

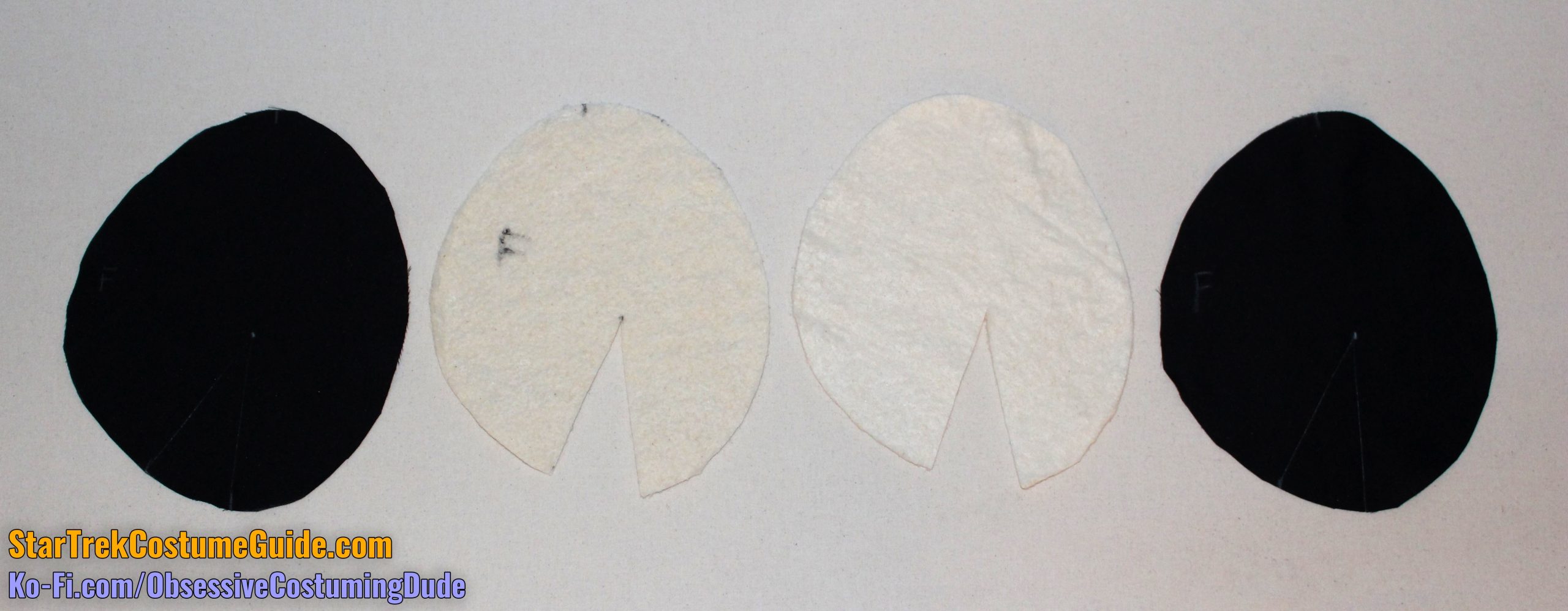

First, cut two pieces of lining and however much padding you want, using the shoulder pad pattern (piece N).

(I like to use lightweight cotton batting for the padding.)

For “normal” shoulder slopes, a mere two layers of padding both looks good and is fairly analogous to the loft of the original pads.

Press the pad into its gently-rounded shape over a tailor’s ham.

Repeat for the other pad.

Hand-sew the shoulder pads to the shoulder seam allowances, leaving the outermost 3” to 3 ½” free.

(Alternatively, attach a pair of snaps to each pad and the corresponding seam allowances, if you want your pads to be removable.)